Calculate container lashing system including weather dependent approach

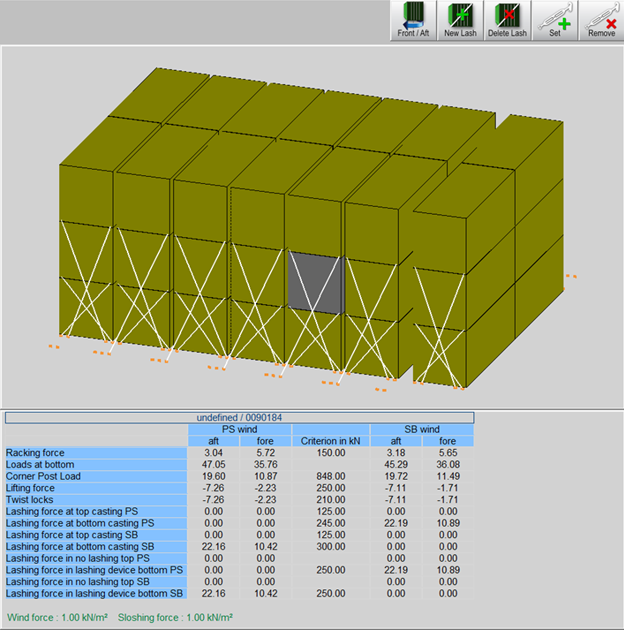

The lashing system is designed to prevent the containers from shifting or tipping over during rough seas. These systems are crucial for safe and efficient transport of cargo containers. Installing these lashing rods, twistlocks, and turnbuckles takes time so you don’t want to use too many lashings. It is best to calculate the forces acting on the containers before a new voyage. In the Lashing module for LOCOPIAS all the container information is already available from the stability calculation. DNV’s Stowlash or BV’s Veristar Lashing calculation kernels are incorporated into the software to calculate all these forces. So the user knows with the applied lashings if the loading condition complies with the rules.

The major advantage of the Lashing module within LOCOPIAS on-board loading computer software is that all information regarding containers is already included in the software. In addition to checking stability the user can directly add lashings to containers already imported with a BAPLIE, for example. This will save labour and prevent errors, especially when the intended loading plan has to be modified, because of e.g. stability or IMDG constraints.

In the case weather-dependent lashing is allowed — with DNV RSCS+ or BV RSSA/WAF class notation, and an actual wave forecast in the case of a voyage of less than 72 hours — this new LOCOPIAS function offers a convenient way of determining the proper lashing arrangement for a specific voyage. In test calculations for such a case we have seen, depending on metacentric height, a significant reduction of number of necessary lashing rods.

Also in the case of unrestricted voyage a direct calculation of lashing forces offers advantages, because it takes the actual stack weight and height, and metacentric height into account, contrary to the standard lashing scheme of the Cargo Securing Manual, which is based on the worst anticipated condition. On the other hand the software adds more safety to the cargo in case the actual loading condition is worse than anticipated. To demonstrate the application, an example calculation has been made and the corresponding demo software can be downloaded.