This module enables you to calculate the actual grain heeling moments according to the requirements of IMO Grain Code, or according to the requirements of the Dutch Shipping Inspectorate.

Selection and definition of grain holds

- Attention

- A compartment which is going to be used to compute grain heeling moments will be defined by one or more subcompartments, which have to comply to the following definition requirements:

- The subcompartments have to be defined from portside to starboard.

- No negative subcompartments are allowed.

- The vertical line through a longitudinal girder has to be a boundary of a subcompartment.

If this is a new project or no existing data is found, you will be prompted to select grain holds. By choosing "Yes", you will be redirected to a list of compartment already defined in Layout, where you are able to select any number of compartments for input through the first column [Selected]. If you choose "No", then you can navigate to the Layout compartment list by clicking on [(De)select grain holds] on the menubar. When exiting from the compartment list, the selected compartments are now visible in a table followed by their subcompartments. The compartment rows are highlighted in colour. You can double-click on a highlighted compartment row to expand/collapse its subcompartment(s) rows. Through the option [Manage] in the menubar you can choose to Expand all or Collapse all the subcompartment rows.

- Selected

- If "Yes" then the grainhold is included in the calculations for the output.

- Name

- Compartment/subcompartment name.

- Void volume table

- The height of the void space in [m] used for calculations and output of the volume table (acc. to Chapter VI, Section I A.a of the IMO Grain Code).

- Volume step m³, Number of steps, Rounded increment

- Those 3 columns are linked:

- The tables are calculated at the volume step (interval) defined here.

- Rounded increment will round (and approximate) the fraction \(\frac{total\_volume}{nr\_of\_steps}\) or \(\frac{total\_volume}{volume\_step}\) depending on the input.

- Void grain moment table

- The height of the void space in [m] used for calculations and output of the grain moment table.

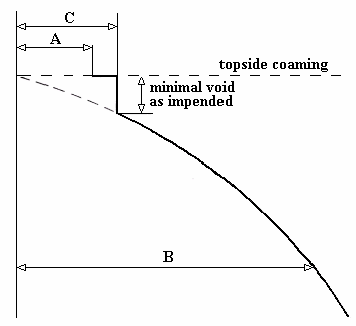

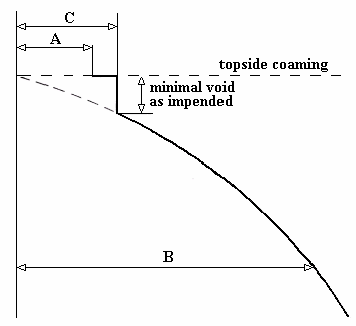

- Girder

- Here you can define whether a girder is present. Only the girders at the topside of the subcompartment have to be defined.

- Breadth CL

- Breadth of the girder from centreline (SB positive, PS negative).

- Underside

- Height of the underside of the girder from baseline.

- Position cross section

- The longitudinal position of the cross-section to be drawn in the output.

- Volume cross section m³

- The grain level with the heeling angle of the hold in m³ to be drawn in the output.

Output of grainhold data

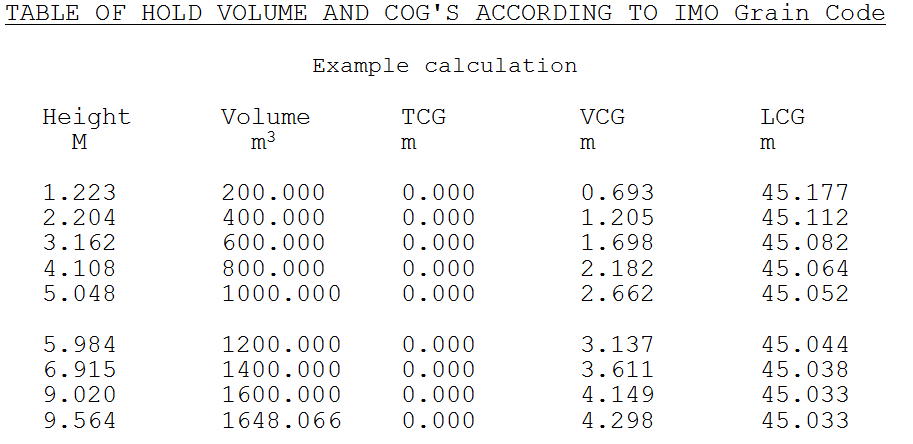

Calculate volume and COGs of selected grain compartments

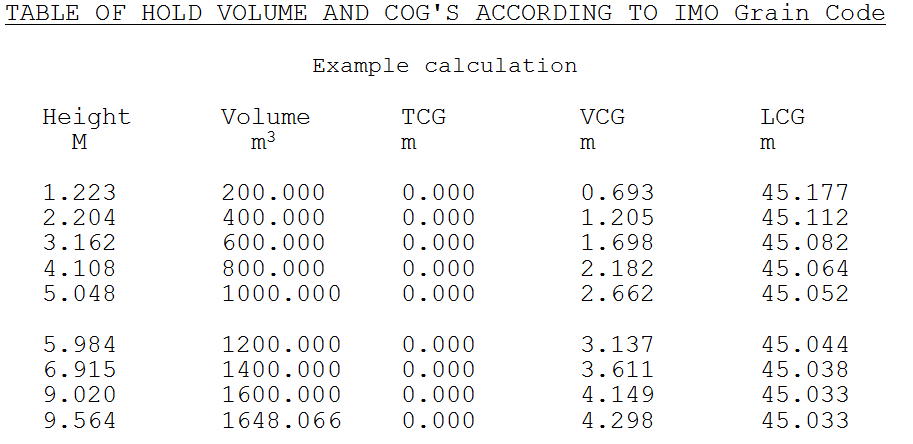

This option calculates the table of volumes and centres of gravity, without heeling angles (see figure underneath).

Table of hold volume and COG's according to IMO Grain code

If the compartment for the grain calculation has been defined including a curved sounding pipe (see Layout), then the output table will also contain a column with the ullage. The ullage is calculated from the top of the defined curved sounding pipe. The top of the sounding pipe will normally be the top of the coaming in case of a grain compartment.

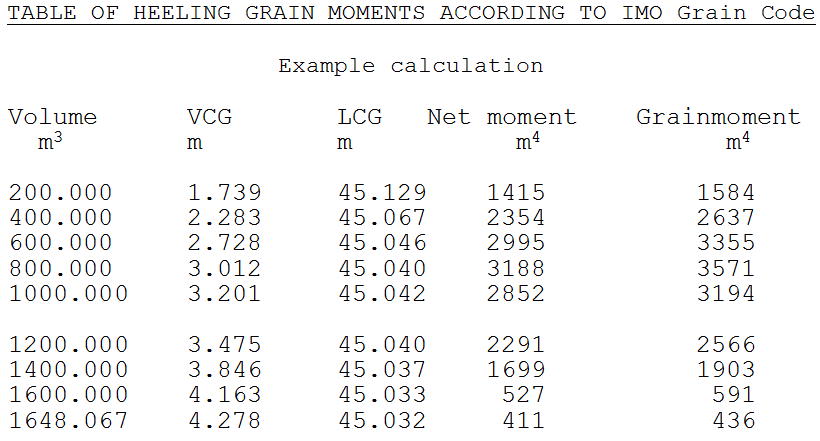

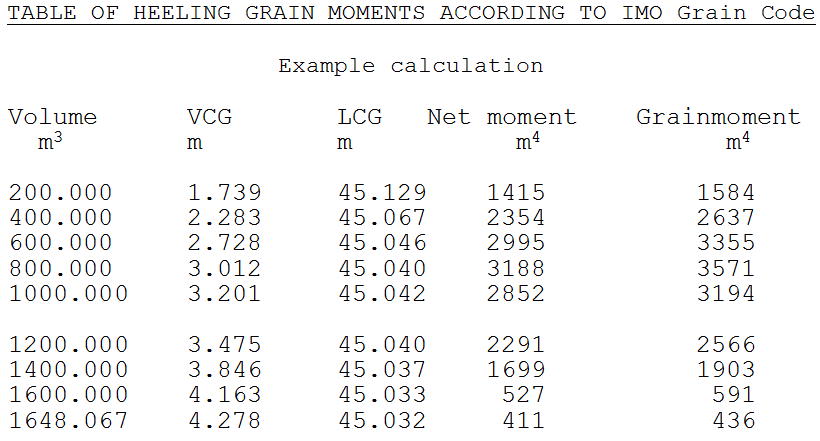

Calculate volume and grainmoments of selected grain compartments

This option calculates the table of grain heeling moments at the prescribed heeling angle (see figure underneath).

Table of heeling grain moments according to IMO Grain code

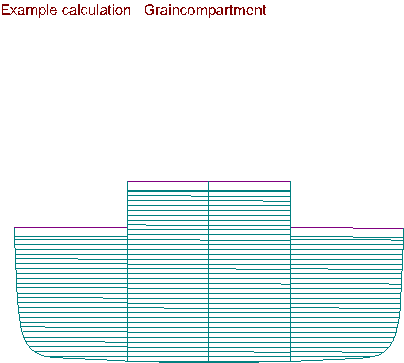

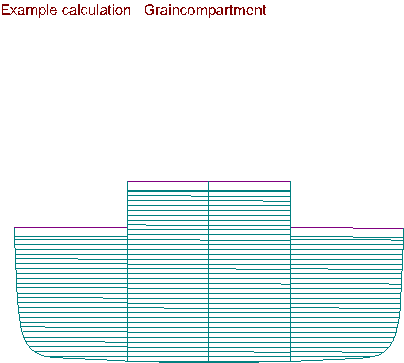

Print cross section of selected grain compartments including void space

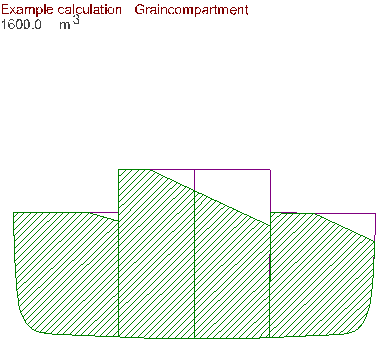

Draws the grain level including void spaces, at zero angle, see the figure below.

Graincompartment 1

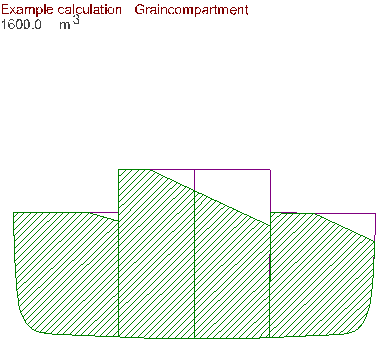

Print cross section of selected grain compartments including grainlevel

Draws the grain level with the heeling angle as prescribed by the regulations, see the example below.

Graincompartment 2

File management

Backups of all data can be made and restored here. For details, refer to Data storage and backups.

Appendix

Appendix 1